Capacitive touch interfaces dominate consumer electronics, but outside of smartphones and tablets, they are not always the best choice. In industrial, medical, transportation, and rugged environments, membrane switches often outperform capacitive touch interfaces in reliability, usability, and long-term performance.

For engineers and product teams designing interfaces that must work under gloves, in contaminated environments, with electrical noise, or under repeated use, the choice between membrane switches and capacitive touch capacitive touch is not about trends. It is about how the interface behaves in real operating conditions.

Fundamental Differences in How the Technologies Work

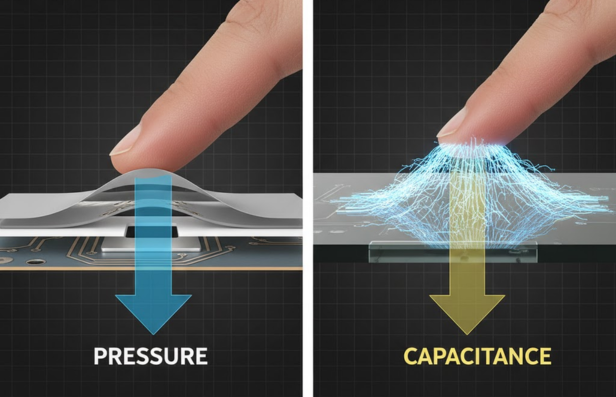

At a basic level, membrane switches and capacitive touch interfaces rely on very different principles.

Membrane Switches

- Activate through physical pressure

- Use printed circuit layers and discrete switch locations

- Provide defined actuation points

- Can integrate graphics, circuitry, tactile feedback, and sealing into one assembly

Because this architecture is built on layered construction rather than surface sensing, understanding how each layer contributes to performance is critical. Our detailed breakdown of the anatomy of a membrane switch and its six critical layers explains how overlays, spacers, circuits, and adhesives work together to create a reliable HMI.

Capacitive Touch Interfaces

- Detect changes in an electrostatic field

- Require conductive input

- Typically rely on continuous glass surfaces

- Depend heavily on firmware tuning and environmental stability

These differences directly influence performance in demanding applications.

Where Capacitive Touch Interfaces Struggle

Capacitive touch interfaces perform well in clean, controlled environments. However, outside those conditions, several limitations become apparent.

Common challenges include:

- Reduced responsiveness with gloves or protective equipment

- False touches caused by moisture, condensation, or liquids

- Sensitivity to grounding and EMI conditions

- Difficulty maintaining accuracy when contaminants are present

- Lack of tactile feedback, increasing user error in no-look operation

These limitations do not make capacitive technology unusable, but they do create scenarios where membrane switches offer a more reliable solution.

When Membrane Switches Clearly Outperform Capacitive Touch

1. Gloved and Tool-Based Operation

Membrane switches activate through pressure, not conductivity. This allows consistent operation with:

- Industrial work gloves

- Medical gloves

- Styluses or tools

- Fingernails or indirect pressure

Capacitive interfaces, even glove-optimized versions, often struggle to maintain consistent sensitivity across different glove materials and thicknesses.

2. Exposure to Harsh Environments

Membrane switches perform reliably in environments involving:

- Water and condensation

- Oils, grease, and chemicals

- Dust and particulates

- Frequent cleaning with disinfectants

When properly designed, a sealed membrane switch assembly prevents false activation from surface contamination. Capacitive touch interfaces can misinterpret liquids or debris as input, creating unpredictable behavior.

3. Tactile Feedback and Operator Confidence

Membrane switches can be engineered with:

- Metal domes

- Polydomes

- Embossed key structures

This provides physical confirmation when a key is actuated. In fast-paced or safety-critical environments, tactile feedback reduces operator error and improves confidence.

Capacitive touch interfaces rely primarily on visual or audio feedback, which may be insufficient in noisy or visually demanding settings.

4. Electrical Stability and EMI Resistance

Membrane switch circuits are inherently stable and predictable. Printed traces and discrete contacts are less sensitive to:

- EMI

- Grounding variations

- Electrical noise from motors or power equipment

Capacitive touch interfaces often require additional shielding, grounding strategies, and firmware tuning to maintain accuracy in electrically noisy environments.

5. Long-Term Reliability and Lifecycle Performance

Membrane switches are commonly designed for:

- Over one million actuations per switch

- Years of continuous daily use

- Minimal calibration drift over time

In contrast, capacitive touch systems may require periodic firmware adjustments as environmental conditions, enclosures, or materials change over the product lifecycle.

From a total cost and reliability standpoint, membrane switches often deliver more predictable long-term performance.

Integration Advantages of Membrane Switch Technology

Beyond operational performance, membrane switches offer integration benefits that are difficult to replicate with capacitive systems.

A membrane switch assembly can combine:

- Graphic overlays

- Printed circuits

- Tactile elements

- LEDs and light guides

- Environmental sealing

- Mounting adhesives

This consolidation reduces part count, simplifies assembly, and improves manufacturing repeatability. Capacitive interfaces typically involve separate glass, sensors, controllers, and software layers.

Applications Where Membrane Switches Excel

Membrane switches consistently outperform capacitive touch interfaces in applications such as:

- Industrial control panels and HMIs

- Medical diagnostic and therapeutic equipment

- Laboratory instrumentation

- Transportation and marine controls

- Food processing and washdown environments

- Outdoor and ruggedized equipment

In these environments, reliability, cleanliness, and repeatability outweigh gesture-based interaction.

Design Considerations for Interface Selection

When evaluating membrane switches versus capacitive touch interfaces, design teams should consider:

- Operator environment and glove usage

- Exposure to liquids, dust, or chemicals

- Need for tactile feedback

- Electrical noise and grounding conditions

- Long-term maintenance and validation requirements

In many cases, membrane switches align more naturally with these constraints.

Industry Perspective

In practice, many manufacturers across industrial and medical markets continue to rely on membrane switch technology for applications where reliability and tactile certainty matter more than multi-touch gestures.

Organizations such as Butler Technologies, which specialize in engineered membrane switches and printed electronics, regularly encounter these tradeoffs when supporting interface designs for demanding environments. Their experience reflects a broader industry trend: application-driven interface selection consistently outperforms trend-driven design.

Key Takeaways

Capacitive touch interfaces have transformed consumer electronics, but they are not universally superior. In environments involving gloves, contamination, EMI, or repetitive use, membrane switches often outperform capacitive touch interfaces in reliability, usability, and lifecycle stability.

For engineers and product teams, understanding these performance differences is essential to designing interfaces that work consistently in real-world conditions.

FAQs

When do membrane switches outperform capacitive touch interfaces?

Membrane switches outperform capacitive interfaces in environments involving gloves, moisture, contaminants, EMI, or where tactile feedback and reliability are critical.

Are membrane switches more reliable than capacitive touch screens?

In harsh and industrial environments, membrane switches often provide greater stability and predictable performance due to sealed construction and discrete actuation.

Why are membrane switches common in medical and industrial devices?

They function reliably with gloves, tolerate frequent cleaning, provide tactile feedback, and maintain consistent performance without calibration drift.

Can membrane switches support modern interface requirements?

Yes. Membrane switches can integrate LEDs, backlighting, complex graphics, and printed electronics while maintaining durability and usability.